Electronic Crockmeters: The Key to Quality Control in Textile Manufacturing

Introduction:

In textile manufacturing, quality control is of utmost importance. One of the key aspects of quality control is ensuring that the color fastness of fabrics is up to standard. This is where electronic crockmeter come in. In this article, we will discuss what electronic crockmeters are, how they work, and why they are important for quality control in textile manufacturing.

What are Electronic Crockmeters?

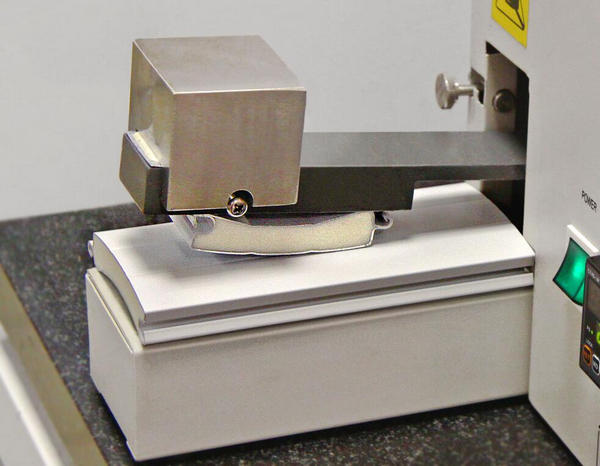

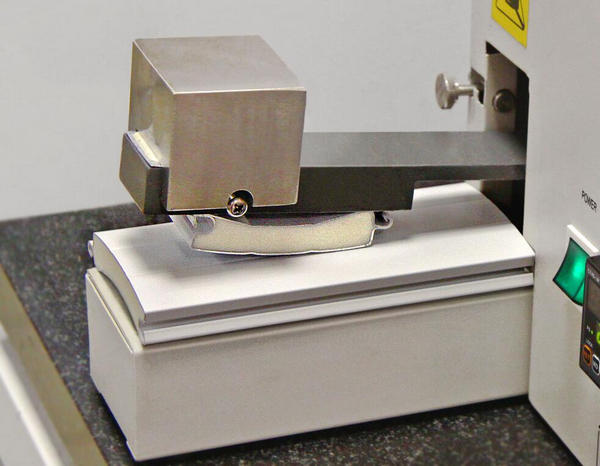

Electronic crockmeters are devices used to test the color fastness of fabrics. They simulate the rubbing or friction that occurs during normal wear and tear of a fabric. The device consists of a rubbing finger which moves back and forth over a fabric sample with a specified force and speed. The amount of color transfer from the fabric onto the rubbing finger is then measured using a spectrophotometer.

How do Electronic Crockmeters Work?

Electronic crockmeters work by simulating the rubbing or friction that occurs during normal wear and tear of a fabric. A fabric sample is placed under the rubbing finger which moves back and forth over it with a specified force and speed. The amount of color transfer from the fabric onto the rubbing finger is then measured using a spectrophotometer.

The spectrophotometer measures the amount of light reflected off the rubbing finger before and after it comes into contact with the fabric sample. By comparing these readings, it can determine how much color has been transferred from the fabric onto the rubbing finger.

Why are Electronic Crockmeters Important for Quality Control in Textile Manufacturing?

Electronic crockmeters are important for quality control in textile manufacturing because they ensure that fabrics meet color fastness standards. Color fastness refers to how well a fabric retains its original color after exposure to various conditions such as washing, sunlight, or friction.

If fabrics do not meet color fastness standards, they can fade or change color over time, which can lead to customer complaints and decreased sales. By using electronic crockmeters, textile manufacturers can ensure that their fabrics meet color fastness standards before they are sold to customers.

Electronic crockmeters also help manufacturers identify potential issues with their production process. If a fabric fails the color fastness test, manufacturers can investigate the cause and make necessary adjustments to their production process to prevent future issues.

Conclusion:

In conclusion, electronic crockmeter are important devices for quality control in textile manufacturing. They ensure that fabrics meet color fastness standards and help manufacturers identify potential issues with their production process. By using electronic crockmeters, textile manufacturers can ensure that their fabrics meet customer expectations for quality and durability.

2023-05-10 10:59