Zipper Tester: The Essential Tool for Any Garment Manufacturer

Zipper is a common connecting device in our daily life, which has the advantages of being simple, fast and convenient, and is widely used in the fields of garments and luggage. However, due to frequent use, zippers are also prone to various problems, such as snagging and breaking. In order to ensure the quality and reliability of zippers, zipper testing is required. This article will discuss the methods and standards of zipper testing in depth.

I. Zipper testing methods

1. Visual inspection method

The visual inspection method is one of the simplest and most commonly used zipper testing methods. The zipper is checked by manual visual inspection for flatness, neatness of stitching, alignment of gears, etc. to judge its quality and reliability. This method is suitable for simple fabric or plastic zippers and is less costly.

2.Manual traction method

The manual traction method is to test the load-bearing capacity of zipper by manual operation. Both ends are fixed on the bracket, and then manual traction is used to simulate the strength under actual use and to observe the load-bearing capacity and durability. This method is suitable for products with medium strength requirements.

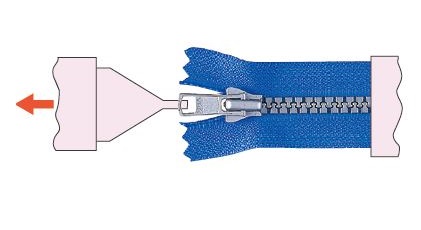

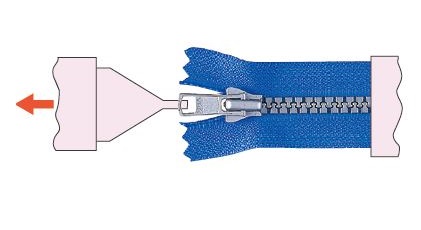

3. Mechanical traction method

The mechanical traction method is used to test the load-bearing capacity of zippers by means of a mechanical device. The zipper is clamped between two jigs and then force is applied through the mechanical device to test its load-bearing capacity and durability. This method is suitable for products with high strength requirements.

II. Zipper testing standards

1.Zipper size

Zipper size refers to the parameters of zipper length, tooth pitch and tooth height. These parameters have different requirements for different types of zippers. For example, zippers for garments usually require small tooth pitch and low tooth height, while zippers for luggage require large tooth pitch and high tooth height.

2. Durability

Durability refers to whether the zipper still keeps good use after many times of use. Durability test can be carried out by manual traction method or mechanical traction method.

3.Twisting and snagging

Twisting and snagging are common problems that tend to occur especially when not used for a long time or when used improperly. Therefore, these situations need to be simulated in the test and their performance observed.

4.Environmental adaptability

Environmental adaptability refers to the performance of zippers in different environments, such as temperature, humidity, etc. This test can be performed by simulating different environmental conditions.

5.Chemical Performance

Zippers may be exposed to various chemical substances, such as water, oil, sweat, etc., during the production and use process. Therefore, their chemical properties need to be considered in the test to ensure that they do not cause harm to the body.

III. Conclusion

Zipper testing is an important part of ensuring product quality and reliability. Different types of zippers require different testing methods and standards, and they need to be adjusted according to the actual situation. Through reasonable zipper testing, we can improve product quality and market competitiveness and provide consumers with a better using experience.

2023-05-09 09:55