What are the main considerations when choosing a tearing tester?

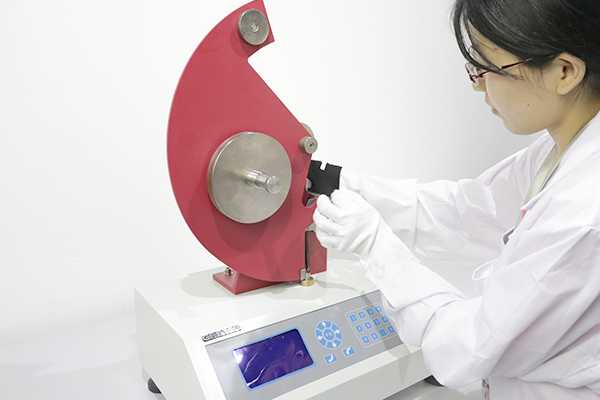

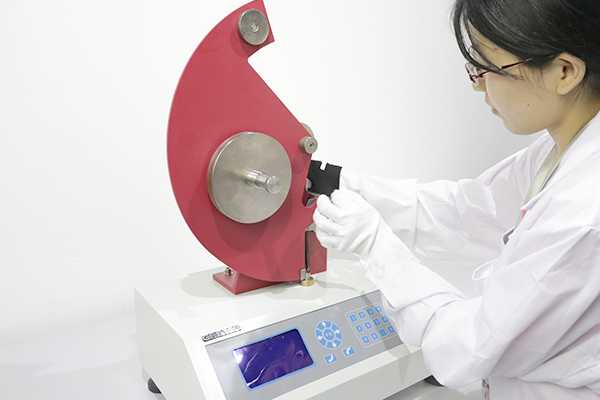

Tearing testers are instruments that measure the force required to tear a sample of material. They are widely used in various industries, such as textiles, paper, plastics, and packaging, to evaluate the quality and durability of materials. Tearing testers can help manufacturers and consumers to ensure that their products meet the desired standards and specifications.

However, not all tearing testers are the same. There are different types of tearing testers, such as pendulum, falling-pendulum, constant-rate-of-extension (CRE), and Elmendorf, that use different methods and principles to perform the test. Each type of tearing tester has its own advantages and limitations, depending on the material being tested and the application.

Therefore, when choosing a tearing tester, there are some main considerations that one should take into account. These include:

- The type and thickness of the material: Different materials have different tearing properties and behaviors. For example, fabrics tend to have higher tearing strength than paper or plastic films. Thicker materials also tend to have higher tearing strength than thinner ones. Therefore, one should choose a tearing tester that is suitable for the type and thickness of the material being tested. For instance, pendulum and falling-pendulum testers are more suitable for fabrics and thick materials, while CRE and Elmendorf testers are more suitable for paper and thin materials.

- The accuracy and precision of the measurement: Accuracy refers to how close the measured value is to the true value, while precision refers to how consistent the measured values are. Both accuracy and precision are important for reliable and valid results. Therefore, one should choose a tearing tester that has high accuracy and precision, and that can eliminate or minimize sources of error and variation. For example, some factors that can affect the accuracy and precision of the measurement are the alignment of the specimen, the clamping force, the calibration of the instrument, the environmental conditions, and the operator skill.

- The ease of use and maintenance: A tearing tester should be easy to use and maintain for the operator. It should have a user-friendly interface, clear instructions, and simple operation procedures. It should also have features that can enhance the efficiency and convenience of the test, such as automatic data collection and analysis, digital display, memory storage, and remote control. Moreover, a tearing tester should be easy to maintain and service. It should have durable components, low maintenance costs, and long service life.

In conclusion, choosing a tearing tester is not a trivial task. It requires careful consideration of various factors that can affect the performance and outcome of the test. By taking into account these main considerations, one can select a tearing tester that is suitable for their needs and expectations.

2023-04-19 11:23