Solving the mystery: Understanding the science of zipper durability testing

A zipper is a connector commonly used in our daily lives to easily connect or separate two pieces of fabric or other materials. The design and manufacture of zippers may seem simple, but it actually involves many scientific principles and technical details. In order to ensure the quality and performance of zippers, zipper manufacturers usually perform various durability tests on zippers to check their tensile strength, degree of abrasion resistance, corrosion resistance, etc. This article will introduce some common zipper durability testing methods and standards, as well as their scientific basis and significance.

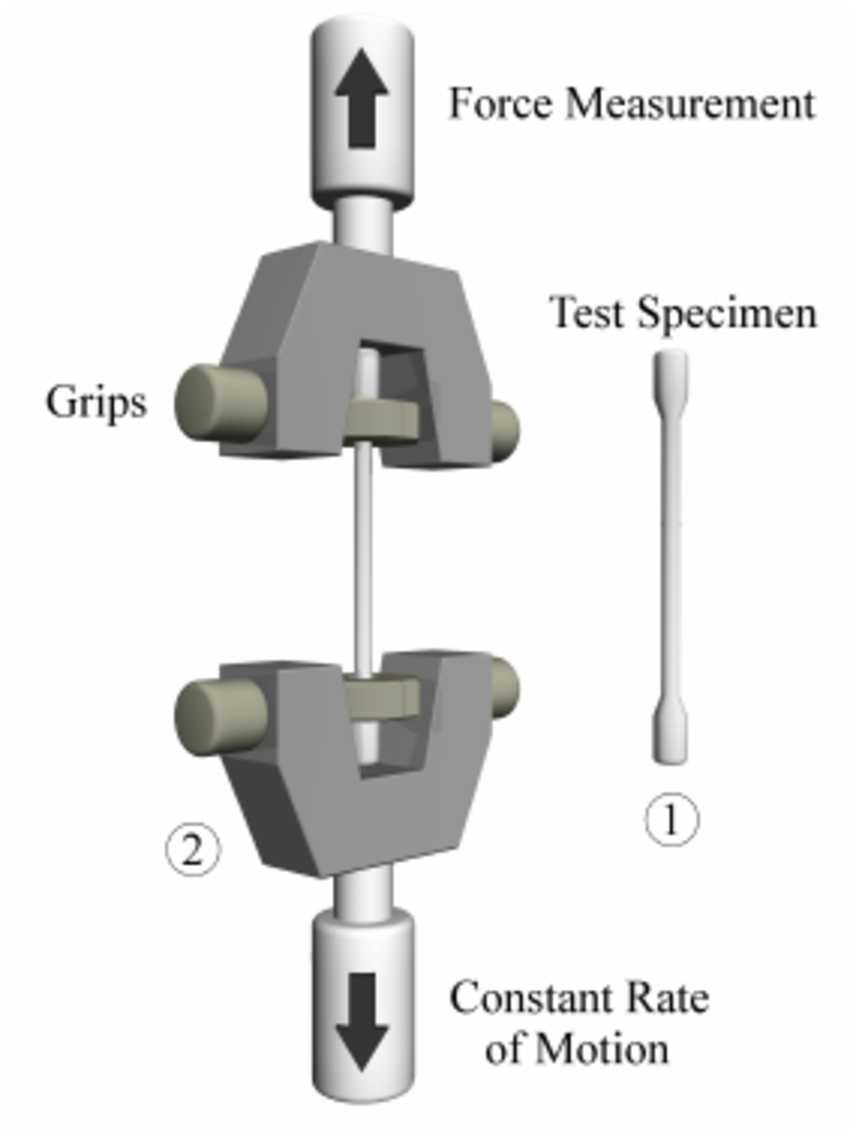

Tensile strength test is to stretch a zipper with a special instrument to measure how much displacement it can withstand under different strengths and when it breaks. This test evaluates the strength and toughness of the zipper and how firmly it is attached to the fabric or other materials. The standards for tensile strength testing vary from country to country and industry to industry, but generally there are several steps:

1. Secure the zipper between two fixtures of the apparatus, one of which is stationary and the other can be moved in a horizontal direction.

2. Start moving the movable jig so that the zipper is subjected to a tensile force and record the displacement of the jig and the force applied.

3. When the zipper breaks, stop moving the jig and record the displacement and force at this point.

4. Based on the recorded data, the tensile strength of the zipper is calculated, i.e. the force applied at the time of break divided by the cross-sectional area of the brek.

The scientific basis for tensile strength testing is Hooke's law, which states that in the elastic range, the force exerted on an object is proportional to the deformation it produces. Hooke's law can be expressed by the mathematical formula

F = kx

where F is the force on the object, k is the coefficient of stiffness of the object, and x is the deformation produced by the object. For a zipper, when it is subjected to a certain degree of stretching, it will produce a certain degree of deformation, i.e., displacement. When the displacement exceeds the limit that it can withstand, it will fracture. Therefore, by measuring the displacement and force, its tensile strength can be calculated.

The significance of the tensile strength test is that it can reflect whether the zipper can withstand a certain level of external force during use without damage. For example, when a suitcase or backpack is filled with items, the zipper will be subjected to a large amount of tension. If the zipper's tensile strength is insufficient, it may cause the zipper to break or fall off, causing items to fall apart or be lost. Therefore, when choosing or buying a zipper, you should pay attention to whether its tensile strength meets your needs.

II, wear resistance test

The zipper abrasion resistance test is a method used to test the quality of zippers, which can simulate the friction and tension that zippers are subjected to in daily use. The zipper abrasion resistance test can evaluate whether the zipper is worn out in long-term use, whether it is easy to break or snag, and whether it can maintain good appearance and function. The steps of the zipper abrasion test are as follows:

1. Sew the zipper to two pieces of fabric to form a closed pouch.

2. Place the bag in a special machine that opens and closes the zipper with a certain frequency and force.

3. After each opening and closing of the zipper, check the status of the zipper and record any abnormalities or damage.

4. Repeat steps 2 and 3 until a predetermined number of tests is reached or a serious failure occurs.

5. Based on the test results, score and classify the zipper to evaluate its abrasion resistance and quality level.

Zipper abrasion resistance test is an important quality control tool that helps manufacturers to improve the manufacturing standards of zippers and also helps consumers to choose the right zipper products. Through zipper wear test, we can ensure that zippers can maintain stable and reliable work under various environments and conditions.

2023-04-17 10:04

- Related News

The importance of battery internal resistance testing in the battery manufacturi

Application and structural principle of high and low temperature test chamber

Application of Small Coating Machine in Polyimide Slurry

Principles and selection methods of laboratory incubators

Evaluation of Moisture Absorption and Rapid Drying Performance of Textiles by Na

Liquid Moisture Management Tester

Paper ring compression strength tester standards