Quality Assurance through Comprehensive Zipper Testing Methods

As one of the common accessories, zippers are widely used in various garments, bags and other fields. However, due to the influence of zipper material, manufacturing process, operating environment and other factors, zippers are also prone to damage, snagging, breaking and other problems during long-term use, which greatly affects the use effect and product quality. Therefore, the strict zipper testing method is one of the important means to ensure the quality of products.

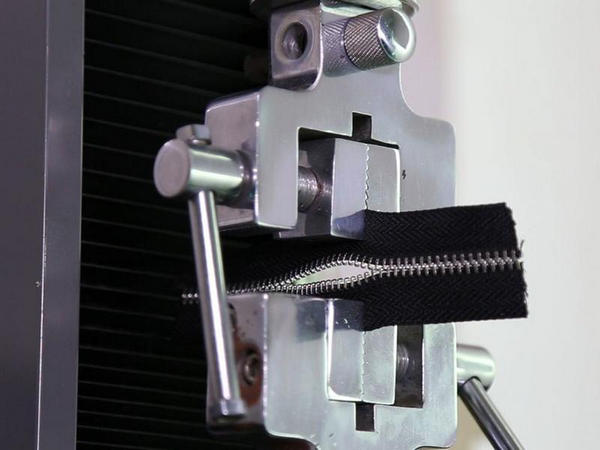

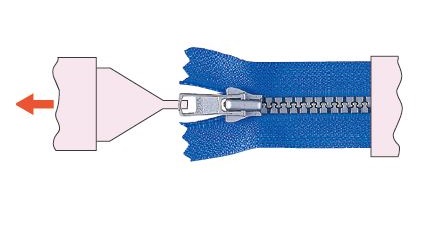

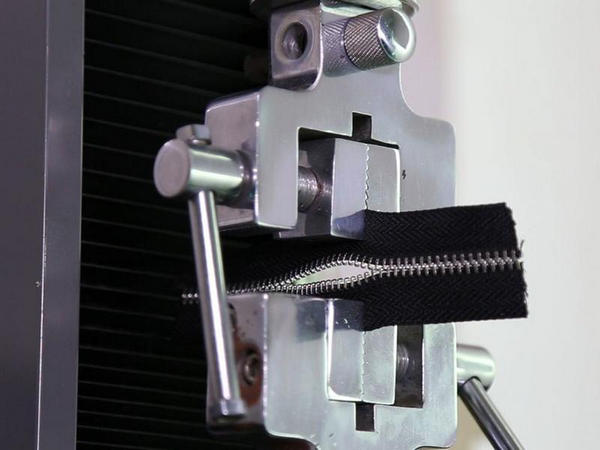

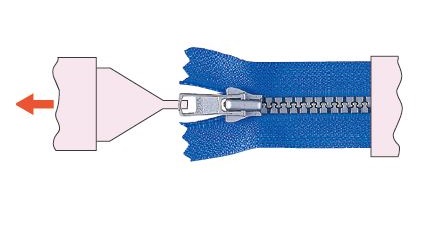

First of all, the standard zipper testing method should include tensile test, abrasion test, locking test, waterproof test and other links. Among them, tensile test is to evaluate the zipper's ability to bear weight, abrasion test is to evaluate the zipper's ability to withstand wear and tear, locking test is to evaluate the zipper's tooth-to-tooth fit, and waterproof test is to evaluate the zipper's sealability after being exposed to moisture. The results of each test directly reflect the strength, durability, precision and water tightness of the zipper material.

Secondly, an effective zipper testing method should also develop a test plan, select suitable testing equipment and environment according to the actual situation, and strive to improve testing efficiency and accuracy. For example, for mass-produced zipper fittings, testing can be conducted by sample sampling, and standard testing time can be reasonably shortened according to the nature of work, testing items and other factors, so as to better ensure product quality and production efficiency.

In short, through a comprehensive zipper testing method can not only strongly ensure product quality, but also make an important contribution to improving production quality and reducing costs. We should continue to strengthen the research and improvement of zipper testing machine to provide more reliable and high quality zipper products for consumers.

2023-04-13 10:19