How to improve the accuracy of UV Aging Test Chamber test results?

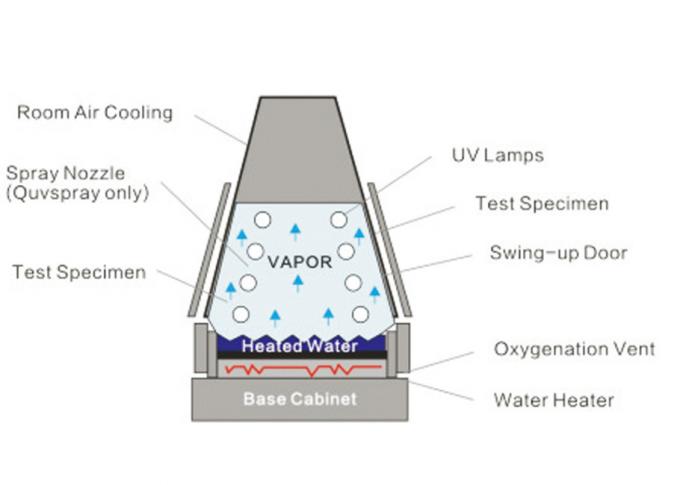

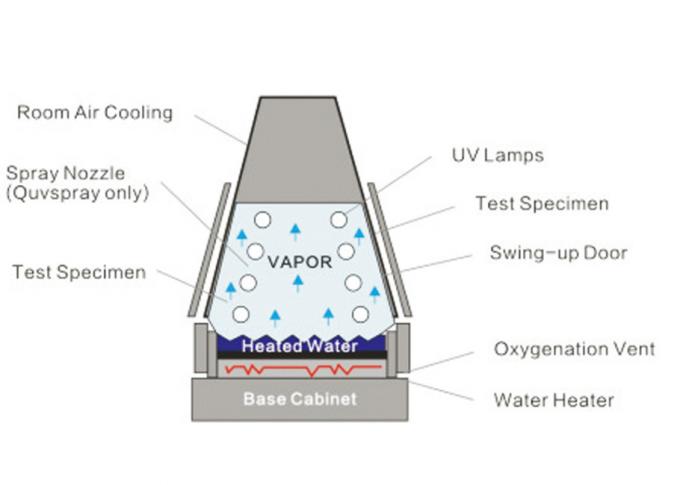

The UV Aging Test Chamber is a device for simulating and evaluating the ageing, degradation and durability of materials in the presence of UV radiation from sunlight. Its main applications are in the testing of light stability, weathering and durability of materials such as plastics, rubber, paints, coatings, inks, textiles and electronic components.

UV Aging Test Chamber can be tested by various standards, such as ASTM G155, ISO 4892, JIS K 7350, GB/T16422.3, etc.

How to improve the accuracy of UV Aging Test Chamber test results?

1. Standardised test conditions: ensure that parameters such as temperature, humidity, UV exposure, period and time inside the test chamber are consistent with the standard conditions.

2. Uniform irradiation: use random oscillation or rotation of the sample to ensure uniform irradiation of the sample by the UV light source.

3. Use of appropriate sample size and quantity: Select the appropriate sample size and quantity according to the standard requirements to ensure the accuracy of the test results.

4. Calibrate the test chamber regularly: regularly check and calibrate the temperature, humidity and UV irradiation parameters of the test chamber to ensure the reliability of the test results.

5. Use stable quality reagents and samples: Use stable quality reagents and samples to ensure repeatability and accuracy of test results.

6. Strictly control the conditions of use of the chamber: avoid unnecessary contamination, vibration, shock and other external factors interfering to ensure the reliability of the test.

UV Aging Test Chamber test methods are generally dry and wet two. The dry method is mainly used to test light stability, weathering and other properties, while the wet method is used to test the fading, fading and other appearance properties in the accelerated aging process. Please contact QINSUN Instruments for more information.

2023-03-29 14:27