What are the care instructions for ASTM Textiles 45 degree flammability tester?

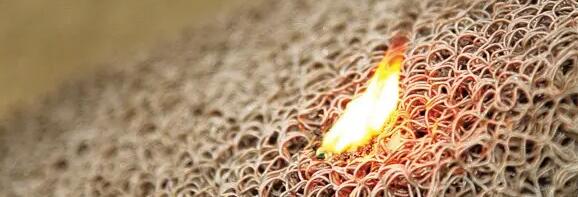

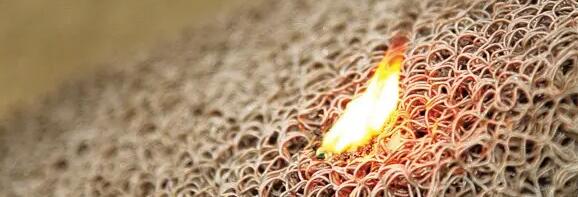

The ASTM Textiles 45 degree flammability tester is suitable for determining the area of damage and length of damage of textiles at 45° and the number of times textiles are exposed to flame when they are heated and melted to a specified length at 45°.

What are the characteristics of the ASTM Textiles 45 degree flammability tester? And what are its maintenance methods? What are its maintenance methods?

The gas tank of the flammability tester should have a pressure reducing valve and the main valve should be reliable.

The combustion tester should be operated in the presence of two people, one is responsible for the operation of the sample test, the other is responsible for supervision, check the gas pipeline for gas leakage before the test, if necessary, open the pneumatic small box to check, such as joints, gas pipes are sealed to avoid accidents, the test, the tester responsible for supervision zui close to the main valve of the gas tank, found abnormalities in time to close the main valve to find the cause, the end of the test After the test, the main valve must be closed tightly.

The combustion tester test chamber should be installed in a test cabinet where the air is not convective but can be naturally ventilated to prevent the air from flowing during the test and to avoid the burner from backfiring. At the end of the test the fan can be switched on to remove the smoke.

The input power of the combustion tester is AC220V±10% and a three-pole socket with an earth wire should be used to ensure reliable grounding.

When the combustion tester is controlled electrically, the burner must be controlled by a time relay to return to the original position after the time has arrived.

The combustion tester test room should be equipped with fire extinguishing equipment. Check the gas circuit regularly.

The fire nozzle should not be subjected to heavy impacts or vigorous bending to avoid damage to the fire nozzle affecting the test.

When using a weighted stop switch, the weight does not need to be suspended too high to protect the stop switch.

Take care to clean the test chamber of any burning residue, as well as any traces of burning in the specimen holder and on the inner wall.

The instrument is made of metal and is susceptible to rusting when exposed to moisture over a long period of time, so keep the test environment dry and apply rust prevention treatment regularly.

Leave a message for a quote on the ASTM Textiles 45 degree flammability tester.

2023-02-15 12:01