What are the characteristics and differences between the different types of film thickness tester?

As industrial production becomes more and more automated, film thickness tester is playing an increasingly important role in inspection systems. It plays an important role in solving the problem of material thickness uniformity in a certain thickness range of film, sheet, paper, foil, etc. and in achieving control of product properties. However, with the progress of technology, there are more and more film thickness tester on the market and accordingly different types of film thickness tester have emerged, and in the course of their work QINSUN instrument engineers often encounter enquiries from customers.

In order to help people in the industry have an understanding of different thickness gauges, so as to have a certain understanding in the purchase or use, Xiao Bian will briefly explain the types and differences of film thickness tester here.

Film thickness tester's brand classification:

According to the different products tested and the different requirements, the types of instruments required are naturally different. The film thickness tester in the current market is mainly divided into handheld, online, contact, non-contact, etc. The brand classification is different, and the corresponding test products are different, of course, the test standards are also different.

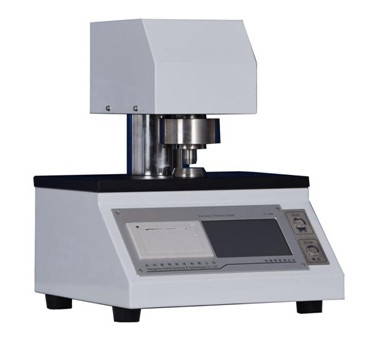

Take CHY-CAfilm thickness tester under QINSUN instrument as an example, which adopts mechanical contact measurement method. This instrument meets the requirements of national and American standards, such as GB_ T_ 6672-2001 Determination of thickness of plastic film and sheet_ Mechanical measurement method; ASTM D374 Standard Test Method for Thickness of Solid Electrical Insulating Materials; ISO 4593, ISO 534 and other mechanical side rear standards are applicable to the measurement of the thickness of films, thin films, diaphragms, paper and other materials with a thickness of 0-6 mm.

The difference between mechanical contact and non-contact film thickness tester:

The mechanical contact film thickness tester has the characteristics of fast response and good real-time performance, and during the test, the data will not be affected by the slight vibration of the sample, let alone the material of the sample. Furthermore, it is convenient and quick to use, easy to operate, humanized in design, and easy to calibrate and maintain, so it is an ideal test instrument for manufacturers.

The main function of the non-contact thickness gauge is information collection and processing. It uses a non-polluting laser to test without contact with the sample. Small, not affected by the measured substance. Compared with the contact film thickness tester, the non-contact thickness gauge is relatively expensive, so the general market price is relatively high, which is not acceptable to ordinary small and medium-sized manufacturers.

According to the specific application, if the sample tested by the user is a material such as plastic film, sheet, diaphragm, paper, foil, silicon wafer, etc., it is the best way to choose a mechanical contact film thickness tester; for rubber, steel, Automobile, machinery, light industry, chemical industry and other industries are not suitable for thickness control of mechanical contact measurement, and can only choose non-contact thickness measurement method.

Many people may think that the precision of the mechanical contact film thickness tester is not as good as the non-contact one. First of all, it needs to be explained that this idea is wrong and one-sided. Taking the "CHY—CAfilm thickness tester" developed by Jinan QINSUN Instruments as an example, its resolution can reach 0.1um, and its measurement accuracy is above 0.5, and it is designed in strict accordance with relevant national standards, so the test results are fully guaranteed.

For more information about the testing principle and specific methods of film thickness tester, you can also leave a message online in addition to entering the company's product page for a detailed understanding.

2023-02-07 11:32

- Related News

The importance of battery internal resistance testing in the battery manufacturi

Application and structural principle of high and low temperature test chamber

Application of Small Coating Machine in Polyimide Slurry

Principles and selection methods of laboratory incubators

Evaluation of Moisture Absorption and Rapid Drying Performance of Textiles by Na

Liquid Moisture Management Tester

Paper ring compression strength tester standards