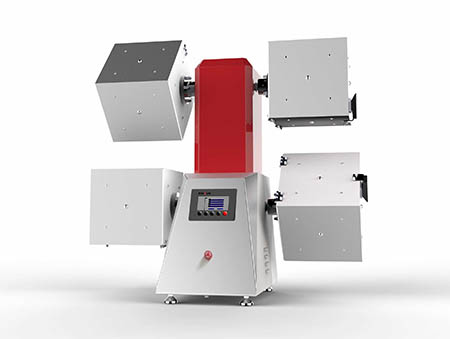

What are the characteristics of the random fluffing and pilling tester?

The flip pilling tester can detect the pilling and pilling performance of fabrics. Under the action of the rotation of stainless steel blades in the independent aluminum alloy test chamber, the fabric to be tested is continuously and randomly rubbed against the cork lining. The test time is controlled by a timer and an audio alarm. Compressed air can also be injected into the test chamber to enhance the turning and friction. effect. There are 2 or 4 test rooms. Laboratory standard compressed air is required.

What is the testing principle of the messy flap pilling tester?

The 105mm x 105mm samples are placed into the test chamber separately and the cork lined walls of the shelf box are rubbed continuously and randomly under the rotating action of the impeller, the timer is set to the specified time and the sound holds tight after reaching the set time, prompting the end of the test. Compressed air is injected into the test chamber during the test to enhance the flip and the air pressure is adjustable.

5 features of the messy flip pilling tester:

1、The whole machine shell paint with high quality spray plastic treatment.

2, The instrument adopts LCD Chinese display, the interface is simple and easy to understand, easy to operate, equipped with metal buttons.

3、With door opening detection, the motor automatically stops rotating when the door is opened, making the instrument safer.

4、One key start, press the start button gas source and motor work at the same time; experiment is completed automatically stop, and buzzer to remind.

5、The rotating component adopts round belt and wheel, the instrument runs smoothly and with low noise.

2023-01-13 11:14