Experts answer questions: textile waterproof testing methods

What kind of textiles are "waterproof"? How do textile testing equipment manufacturers test for "water resistance"? We invite QINSUN textile testing instrument experts to explain the textile waterproof test method.

1. What does "waterproofness" of textiles mean? What indicators are there to measure?

The waterproof performance of the fabric can be measured by the characteristic indexes of the water level, hydrostatic pressure resistance level and water penetration. In short, the hydrostatic pressure resistance level is water impermeability, and the staining level is water repellency.

Hydrostatic pressure resistant textiles are made by coating finishing or lamination lamination finishing, which makes the fabric resistant to water penetration even under the action of external water pressure, preventing water penetration and preventing the human body or objects from getting wet. It is widely used in outdoor sports' rushing clothes, tablecloths for home use, raincoats and umbrellas for daily use, swimsuits and diving suits, etc. Now there are two main types of hydrostatic pressure resistant fabrics: one is laminated composite waterproof fabric, is the use of special adhesives and ordinary fabrics through the lamination process compounded together to form a waterproof laminated fabric, lamination can be two-layer fabric or multi-layer fabric; second is coated waterproof fabric, that is, the fabric through direct or transfer method coating process, making the fabric surface is closed for coating agent, and thus obtain waterproofness.

Water-repellent fabric is the use of low surface energy finishing agent on the surface of the fiber, so that the critical surface tension of the fabric is reduced to not be wetted by water, mainly the application of the "lotus leaf effect" principle. Water repellent finishing is through the finishing agent, so that the surface of the fabric to obtain a smaller surface tension than water. Water drops on the fabric will fall in the form of water droplets, and will not wet the surface of the fabric.

2. What should I pay attention to in the hydrostatic pressure test?

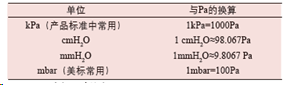

The hydrostatic pressure resistance according to different test standards need to use different units, the common unit conversion is shown in the following table.

Common product standards on the rating results are different, see the table below.

3. In the testing process, what is easy to operate improperly? How to avoid?

In the water staining test requires attention to several issues.

(1) for the elasticity of the larger fabric, in the fixture clamping can not pull the fabric, otherwise it is easy to lead to a larger gap in the fabric, water droplets infiltration wetting fabric, resulting in inaccurate test results;

(2) after the end of the spray hold fixture for knocking, the strength should be uniform and moderate, the strength is too light will make water beads residue, too much strength is easy to cause the fabric from the fixture, will affect the assessment of the water staining phenomenon;

(3) to regularly calibrate the instrument, when the spray water flow is found to have blockage phenomenon or spray time has abnormal, to promptly clean up the spray port or replacement, so as not to affect the accuracy of the test.

4. In the hydrostatic pressure test need to pay attention to what?

(1) when placing the fabric to be first to the fixture air discharge, so that the front of the fabric against the water and then clamping, to avoid the impact of air pressure on the water pressure leads to inaccurate data;

(2) in some composite fabric testing, the reverse side of the fabric is not waterproof, so you need to cut the test sample larger than the instrument sink, to avoid water penetration into the fabric affect the assessment of the hydrostatic pressure phenomenon.

5. What factors affect the hydrostatic pressure resistance of the fabric?

(1) the influence of yarn. The thickness of the yarn: for the moisture-absorbing fiber woven into a compact fabric, due to the existence of the capillary effect, reduce the yarn radius, can improve the fabric's resistance to water penetration. Yarn elasticity of good or bad: by the role of water pressure, good elasticity of warp and weft yarn easy to elongate, which leads to the formation of adjacent warp and weft yarn gap, water beads easier to seep through, making the fabric water pressure resistance value is reduced.

(2) the impact of the fabric. The thickness of the fabric: the thicker the fabric, the greater the wet resistance, the greater the water pressure resistance value. The tightness of the fabric: the increase in the distance between the yarns will directly affect the level of water resistance pressure. Generally the tighter the fabric structure, the better its resistance to water penetration.

(3) The influence of the coating. Coating thickness: the coating is too thin, the coating agent is uniform throughout the fabric and has a certain degree of fastness. The better the quality of the coating, the better the water seepage resistance.

QINSUN is a textile testing instruments supplier with years of R&D and export, welcome to order!

2022-06-15 10:44

- Related News

The importance of battery internal resistance testing in the battery manufacturi

Application and structural principle of high and low temperature test chamber

Application of Small Coating Machine in Polyimide Slurry

Principles and selection methods of laboratory incubators

Evaluation of Moisture Absorption and Rapid Drying Performance of Textiles by Na

Liquid Moisture Management Tester

Paper ring compression strength tester standards